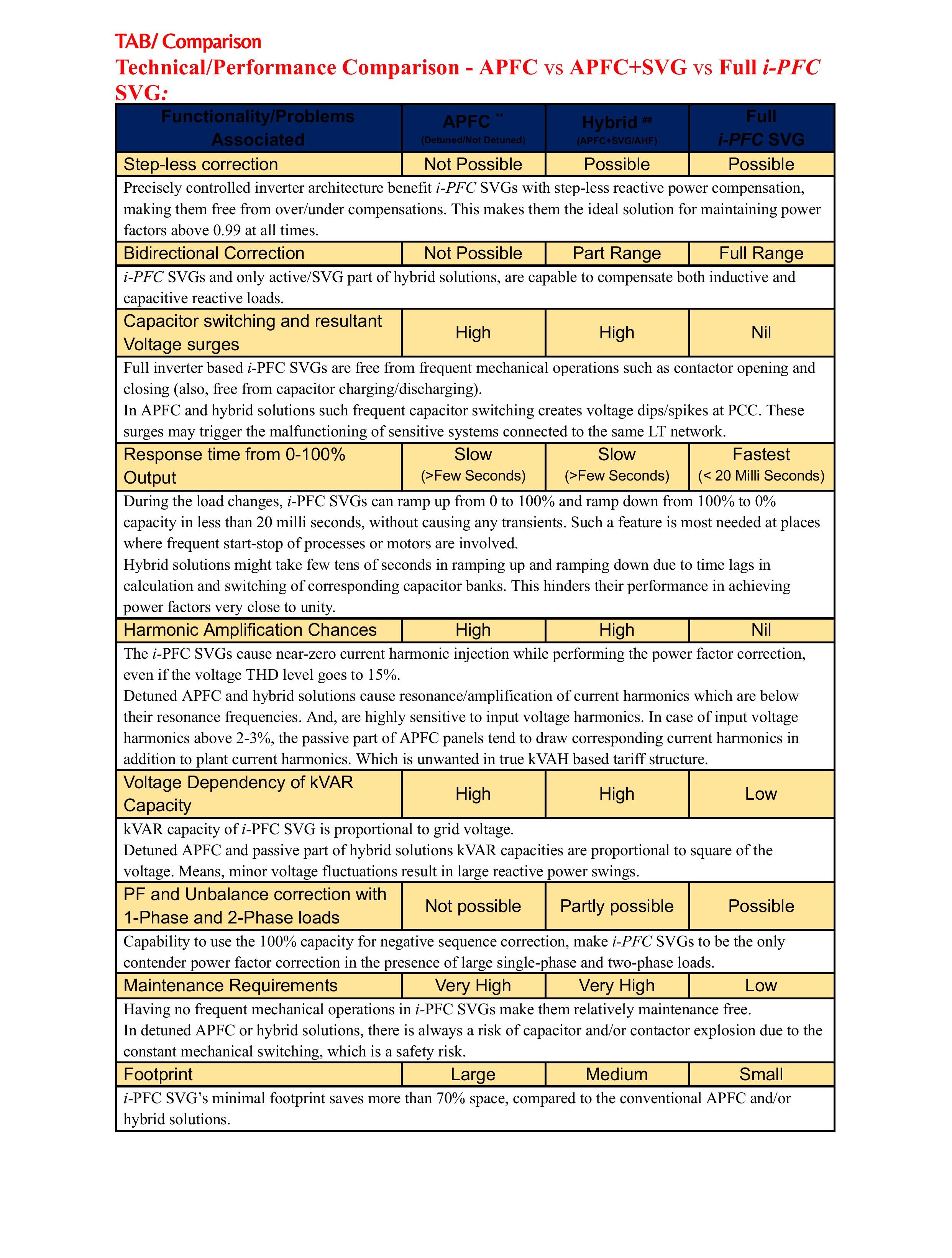

| i -PFC SVG Features | ||||

| Step-less Correction: | Precisely controlled inverter architecture benefit i -PFC SVGs with step-less reactive power compensation, making them free from over/under compensations. | |||

|---|---|---|---|---|

| Bidirectional Correction: | i -PFC SVGs are capable to compensate both inductive and capacitive reactive loads. | |||

| Capacitor switching and resultant Voltage Surges: | Full inverter based i -PFC SVGs are free from frequent mechanical operations like capacitor switching, preventing voltage dips/spikes. | |||

| Response time from 0-100% Output: | During the load changes, i -PFC SVC can ramp up from 0 to 100% and ramp down from 100% to 0% capacity in less than 20 milli seconds, without causing any transients. Such a feature is most needed at places where frequent start-stop of processes or motors are involved. Hybrid solutions might take tens of seconds in ramping up and ramping down due to time lags in calculation and switching of corresponding capacitor banks. This hinders their performance in achieving power factors very close to unity.. | |||

| Harmonic amplification Chances: | The i -PFC SVGs cause near-zero current harmonic injection while performing the power factor correction, even if the voltage THD level goes to 15%. Detuned APFC and hybrid solutions cause resonance/amplification of current harmonics which are below their resonance frequencies. And, are highly sensitive to input voltage harmonics. In case of input voltage harmonics above 2-3%, the passive part of APFC panels tend to draw corresponding current harmonics in addition to plant current harmonics. Which is unwanted in true kVAH based tariff structure. | |||

| Voltage Dependency of kVAR Capacity: | KVAR capacity of i -PFC SVG is proportional to grid voltage. Detuned APFC and passive part of hybrid solutions kVAR capacities are proportional to square of the voltage. Means, minor voltage fluctuations result in large reactive power swings . | |||

| PF and unbalance correction with 1-Phase & 2-Phase loads: | Capability to use the 100% capacity for negative sequence correction, make i -PFC SVGs to be the only contender power factor correction in the presence of large single-phase and two-phase loads. | |||

| Maintenance Requirements: | Having no frequent mechanical operations in i -PFC SVGs make them relatively maintenance free. In detuned APFC or hybrid solutions, there is always a risk of capacitor and/or contactor explosion due to the constant mechanical switching, which is a safety risk. | |||

| Footprint: | i -PFC SVG's minimal footprint saves more than 70% space, compared to the conventional APFC and/or hybrid solutions. | |||

| i -PFC SVG Specifications | ||||

|---|---|---|---|---|

| Plant Input Conditions | ||||

| System Voltage (RMS) | 350 - 480 V | |||

| System Frequency (Hz) | 50 ± 5% | |||

| Operating temperature range | 0 to 450C | |||

| Product Specification | ||||

| Semiconductor Devices | IGBTs (3-Level Topology) | |||

| Maximum Reactive Power Output @480V | 125kVAR | |||

| Step-less Compensation Range | -100kVAR to +125kVAR | |||

| Rated RMS current Output | 150A | |||

| i -PFC configuration | 3P3W | |||

| Power Factor Correction | Yes | |||

| Load Current Balancing | Yes, Negative Sequence | |||

| CT Requirement | 3CTs with 1A or 5A Secondary | |||

| CT Position | Load Side / Source Side | |||

| Integrated Short-Circuit Protection | Yes | |||

| Dimensions | 800 x 890 x 330 | |||

| i -PFC Control and Paralleling | ||||

| Controller | ARM based MCU | |||

| Control Method | Adaptive Artificial Neural Networks (ANN) | |||

| Dynamic Response Time | 100 microseconds | |||

| Correction Time | 10 milli seconds | |||

| Parallel Operation | Upto 50 modules per CT set | |||

| System Integration | ||||

| CT connections between modules | Daisy Chain Type | |||

| Display | 7" TFT Touch-Screen Display | |||

| Software for PC Interface | InstaView | |||

| Cloud Connectivity | Yes | |||

| Color | Standard | |||

| Noise Level | less than 65dB | |||

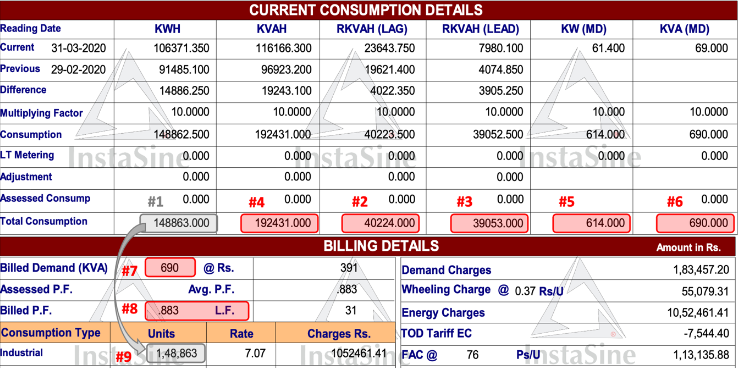

Below is a snapshot of a bill from (one of our clients) for the month of March-2020: